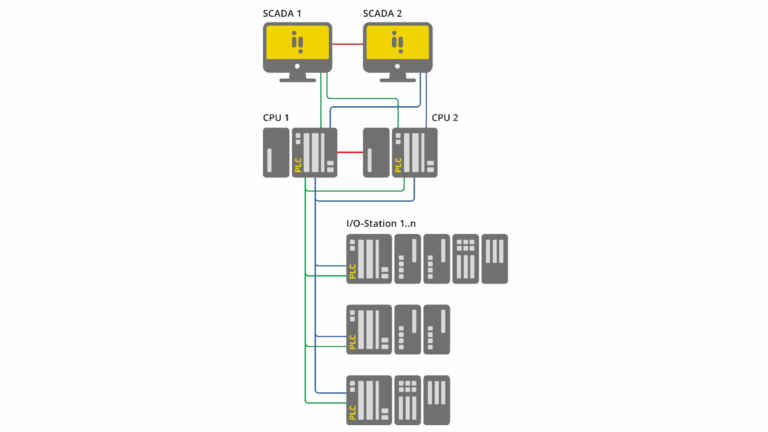

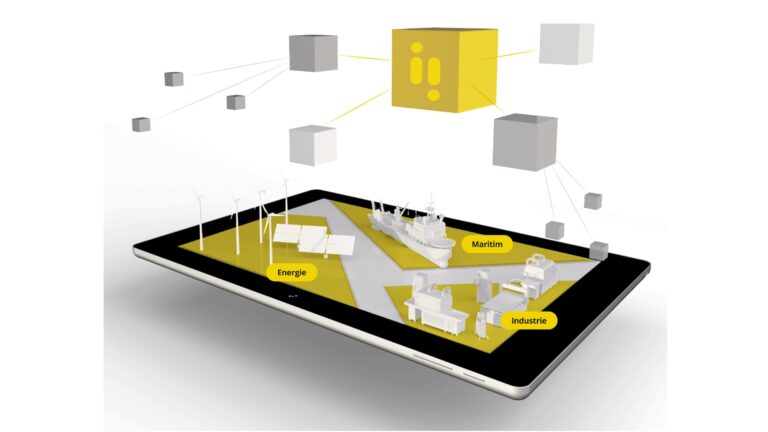

Bachmann electronic presents a scalable smart maintenance solution for condition monitoring in the maritime environment. It allows for the gradual introduction of condition monitoring that can be flexibly adapted to the requirements of mechanical and plant engineering as well as the process and manufacturing industries. This approach enables companies to optimize their maintenance processes step by step without having to make immediate, comprehensive investments.

In the first step, existing process data is systematically recorded and evaluated without the use of additional sensors. Condition monitoring is integrated directly into the control environment, ensuring fast commissioning and close coupling with other system data. In the second step, the system is expanded to include specific sensor technologies.

The third stage involves the integration of a standardized CMS function. Here, not only more data is obtained from the AIC module, but it is also linked to a kinematic system model. This intelligent coupling is permitted to allow for more precise diagnostics, such as the identification of damage to bearings or gears long before a failure is imminent. The evaluation takes place directly on the controller, minimizing response times and backing up data consistency. In the fourth and final step, the system becomes a predictive maintenance solution: continuous monitoring enables critical wear to be detected at an early stage and early warnings to be triggered before damage leads to costly downtime.

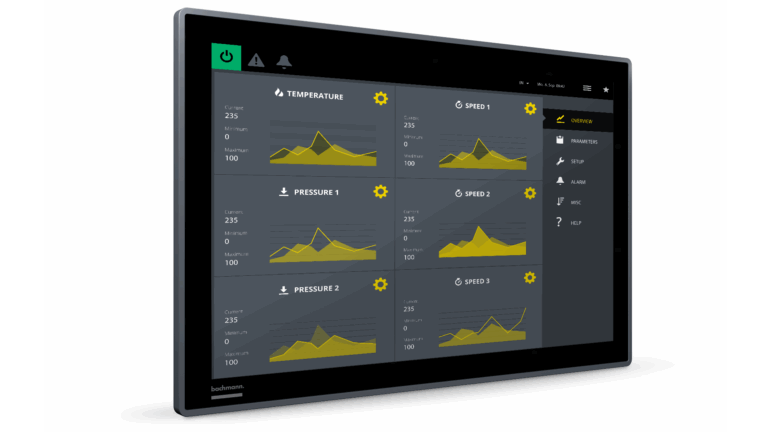

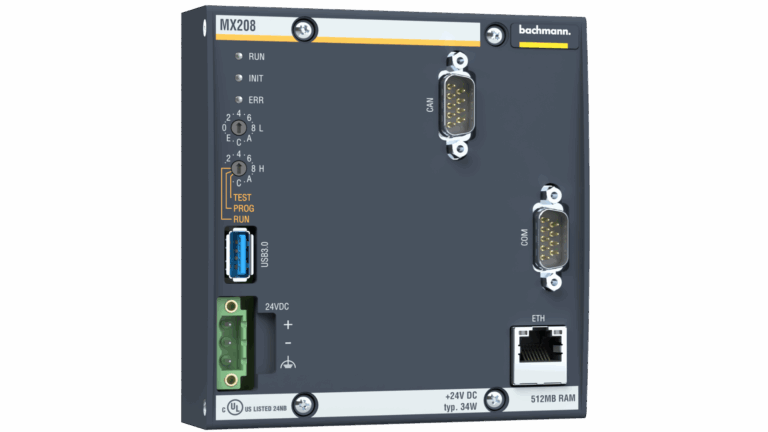

These monitoring solutions are based on robust and certified hardware components such as the AIC206 and AIC214 modules for recording vibration data and the CMSPLC software as a standardized application platform. In addition, WebLog Suite, a powerful condition monitoring software, offers a holistic approach to data management and data analysis.